As a pioneer and dynamic company, Lucid Engineering is leading the way in engineering design and solutions for factory automation during the Industry 4.0 era.

Designing an Automatic Machine to replace a set of Six Manual Process Operations.

A fully Automatic Machine to Draw a multistrand Steel cable to specific length, Insert a metal end (Anchor) in a thread-through-eye of the needle operation on both ends, Swage to secure the Anchors in two 8 Ton Presses and then conduct a Pull Test as verification. All servo motor driven movements to allow 75 variants of parts to be made with touch screen changeover by Operator. Walking Beam transport, Vibratory Feeder for Anchors and Laser Sensors to track anchor position, Cable end etc. Single Operator manning Three Machines simultaneously.

Automatic with low skill to set and operate, Low Maintenenace,High Productivity with 10 Seconds Cycle Time, Zero defect with final Pull Test.

Designing an Automatic Machine to replace a Manual Assembly of Stator Core to Stator Housing using Heat Shrinking Process.

A fully Automatic Machine to allow the Operator to place the Stator Housing and Stator Core in two separate locating Jigs in the Machine. Automatic Cycle to start Heating the Stator Housing by Induction Heating while monitoring the surface Temperature continuously until a set temperature is reached. After which the Coil to be withdrawn and Stator Core inserted to the desired depth to complete assembly with verification of depth distance confirmation with value.

Automatic with low skill to set and operate, Low Maintenance, Zero defect to safeguard against scraping of High cost Stator Housing.

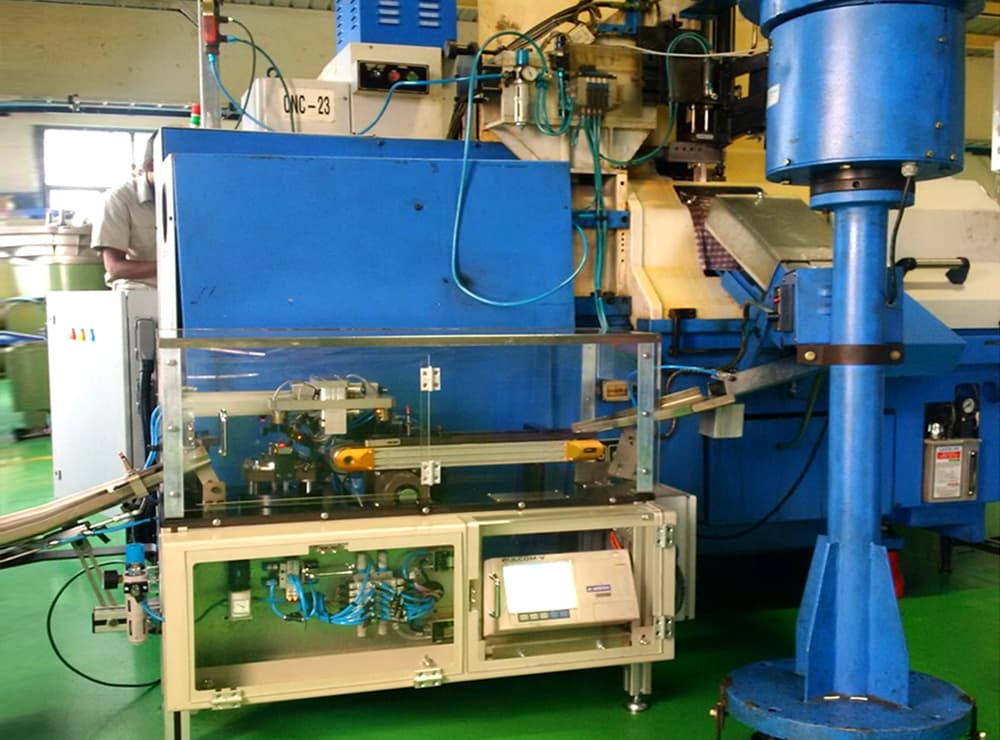

Designing an Automatic Machine to replace a Manual checking of Hard Turned Bearing Rings and making manual corrections to the CNC Turning Process.

A fully Automatic Machine to measure machined Rings and provide input to CNC Turning Centre PLC by way of trend analysis from automatic Post Measurement.

Machine offset correction in a automated way as per programmed algorithm and elimination of manual error of judgment by Operator. Improving the process Cpk.

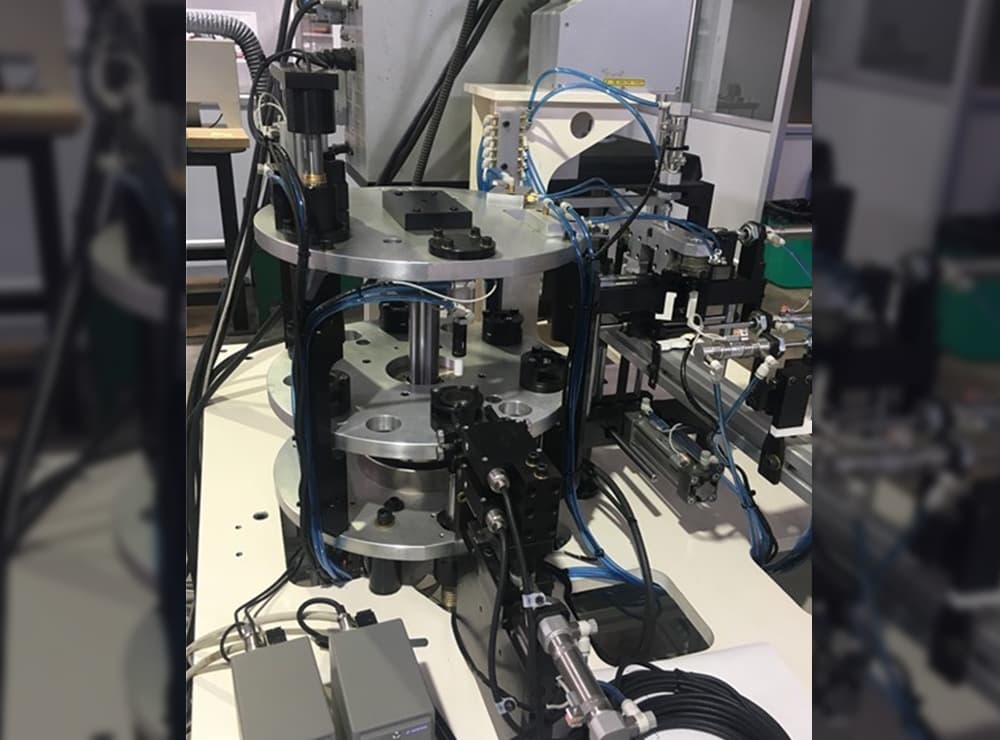

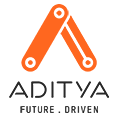

Designing an Automatic Machine to measure Diameters and heights on a finished Engine Tappet Cup to sort for Accept or Reject dispositions and then Laser Mark on the Accepted part data from Measurement with date stamp.

A fully Automatic Machine to measure Diameter in two planes (For Diameter Size and Taper), Crown of Tappet dimension and the Top area Thickness in a continuous rotary indexing machine and convey the parts on separate conveyors if Okay or Not Okay. Outgoing Okay part to be inverted below a Laser Marking Head and inscribed with thickness value Class and the Julian date.

Fully Automatic Process. Changeover for two part numbers. Zero defect end-of-line Inspection Machine for 100% Outgoing quality of output.

Designing a set of Assembly Stations for the Assembly of various parts that constitute a Switch Reluctance Type Motor.

A fixture based manual Press and Assembly Stations to make the progressive assembly of the Motor.

An assembly line to be flexible to make any number of variants with minor fixture changes and small batch capability.

Designing an Automatic Machine to measure Diameters and heights on a semi-finished Gear Pinion Blank to sort for Accept or Reject dispositions.

A fully Automatic Machine to measure Diameter in two planes, Measure heights of the part, Measure Parallelism and Bore Diameter and Run-Out of the Outer Diameter with respect to Bore.

Fully Automatic Process. Changeover for three-part numbers. Zero defect end-of-line Inspection Machine for 100% Outgoing quality of output.

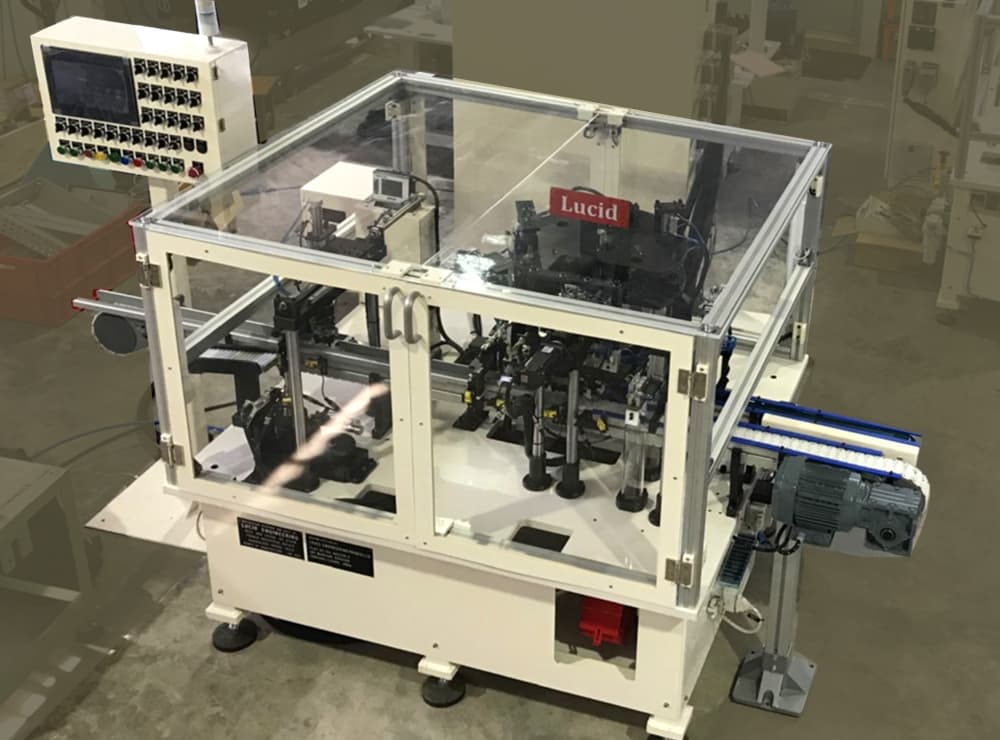

Designing a semi-Automatic Machine to measure the Rotational Lash Value of a Drive-Axle assembly by plotting the graph of the Torque versus Angle graph and drawing tangents to arrive at the value using a software.

A semi-automatic Machine to clamp the Drive Axle on spline ends. Application of Torque through a Servo driven Worm Gear Box and measurement of Rotation angle while monitoring the torque being applied through a torque sensor in-line with the axle. The data captured and converted to a graph giving the Lash value in the Joints by computation software.

Flexible machine with sub 10% Repeatability and ideally used in the Quality Laboratory for qualifying a batch of Axles assembled with sample checked on the machine.

Designing a semi-Automatic Machine to make Needle Bearing Assembly to a Pinion with Circlip insertion. Second Operation of assembly of Pinions to Planet Shaft. Verification of Torque and auto change in tonnage for pressing depending on recipe selection by Operator during changeovers.

A semi-automatic Machine to make a Bearing assembly to a Pinion Bore with end circlips to retain. Torque checking with trip clutch arrangement. Second Press in the machine having tonnage provided by Hydraulic actuator having a servo-controlled DC Valve to change via program for two variants.

Robust Production equipment to ensure assembly, post checking and ergonomics for Operator.

Designing a set of Assembly Stations for the Assembly of various parts that constitute a 12” Hub Motor of EV-Scooter.

A fixture based manual Press and Assembly Stations to make the progressive assembly of the Motor.The processes complete the motor assembly including Bearings,Covers,Shaft,Rotor,Stator and Seals with Torque tightening of Bolts.

An assembly line to be flexible to make any number of variants with minor fixture changes and small batch capability. Poka-yoke features to protect against missed or wrong assembly. Load versus Displacement graphs in all Press Stations and ensuring all bolts are tightened to required torque.

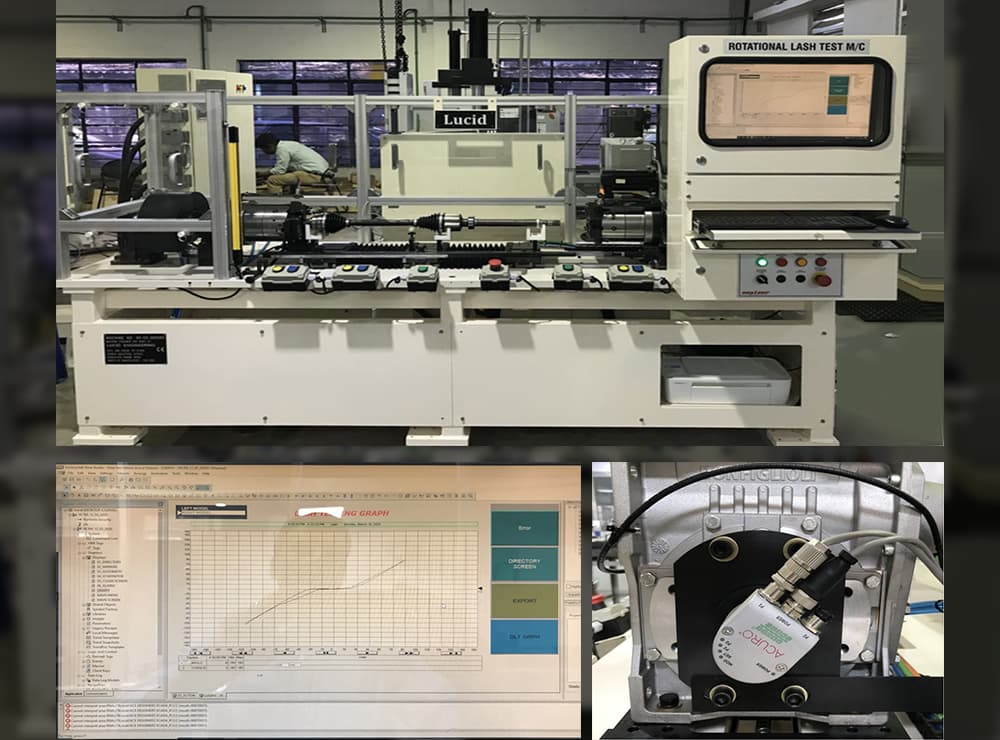

Designing a Automatic Machine to measure and sort Bearing Ring Diameter for Size,Taper,ovality and dispose into Okay/Rework/Scrap compartments. Fast cycle within 2 seconds and sub-micron Repeatability.

A fully-automatic Machine which uses a Cam driven mechanism for moving the ring into a high-precision fixture for rotation while a gauging head checks the diameter in two planes to record the dimensions with a Marposs nano-unimar.The diameters give the size, taper and ovality of the part. The automated disposal system then moves the rings into separate chutes or a scrap box with complete tracking of disposition via sensors to ensure 100% Okay or defect disposition.

Very High precision, sub-micron repeatability below 6% of size tolerance and a 2 second Cycle time.

Designing a Automatic Machine to make Radial Clearance of a Bearing while in Rotation and classifying into Normal or C2,C3.C4 classes. Disposing scrap Bearings into a Red bin and also confirming the Inner Ring size for okay/Not Okay status.

A fully automatic Machine which works with Cam actuated loading and un-loading arrangement. Bearing in held in a precision mandrel and the load application is done with measurement using precision probes in the Outer Race and Inner Race of the Bearing. The Bearings are then diverted by the automation into the output chute or swiped into V Blocks on the machine depending on the Bearing clearance classes. Rejected Bearings drop into a Red Bin container box.

High precision checking arrangement. Automated ,movements and zero defect disposition. Repeatability within 10% of tolerance of Radial Clearance

The complete Mechanical Fixturing with Part locaters and the Robot traverse Servo driven Gantry were designed and built by Lucid Engineering for Madox Technologies. The integrated Robotic Weld project delivered to Gandhi Automation. This Robotic Cell reduced the total cycle time of Building one Factory Dock Leveller from 8 hours to 1.5 hours and resolved the productivity issue for the customer greatly. Besides making the process ergonomic by way of welding fume inhalation and providing product consistent in quality.

The versatile and light weight motorised Gripping Arm attached to the tending Robot designed and built by Lucid Engineering for Madox Technologies is now functioning in full automation at ITC Bangalore. The gripping arm can perform several functions including adapting to different sizes of Carton boxes, lift and invert the Box without crushing the contents yet hold the box and invert. Effectively relieving humans from the activity which makes them prone to health disorders caused by inhaling tobacco fumes from the bale.

Learn more about the latest developments in our areas of expertise, experience, and technology.

Find insightful articles discussing the latest industry trends and new possibilities for emerging automation technologies.

Access our most recent news based on daily or technical press and ad hoc communications.

Check out our success stories about solving unique customer issues with efficient, innovative solutions.